Specifications

V-BOX®

RIPPLE AND NOISE

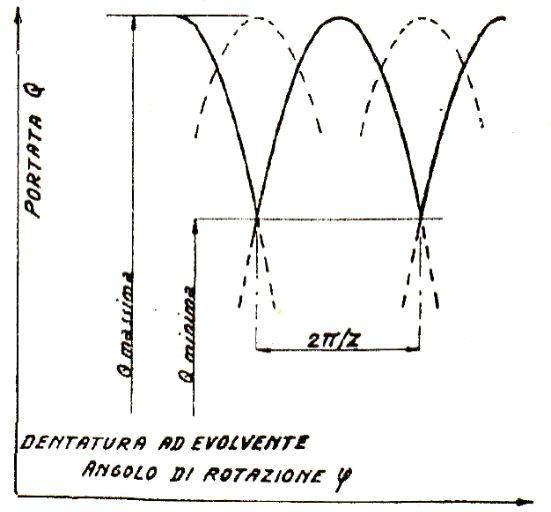

Each kind of oil pump has a certain degree of delivery irregularity; the phenomenon has been well known for a long time; for example these hand made sketch from an old paper (Prof. Bonacini 1961) showing a gear pump kinematic irregularity. Delivery irregularity, as well as the pressurization of the pump transfer volumes and the irregularities of the leakage, generate a pressure ripple in the powered circuit.

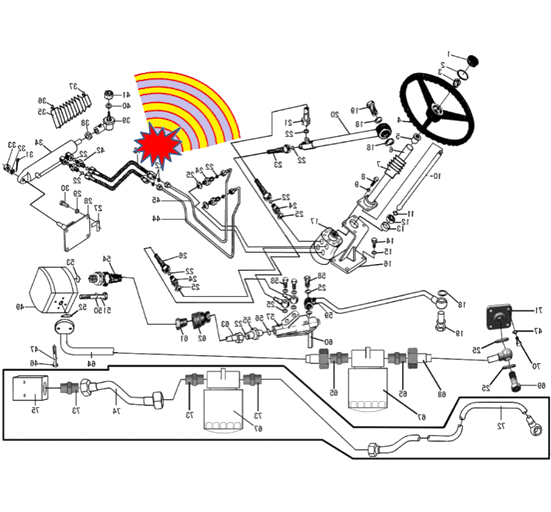

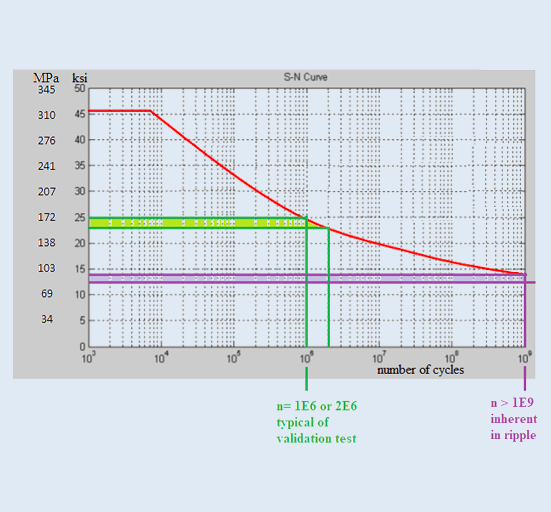

The pressure ripple causes vibrations and noise often far from the pump, which generate overloads and consequent failure due to structural fatigue of the components, especially if the frequency of the pressure ripple corresponds to a natural frequency of some component in the application.

- It is often difficult to identify the components behavior in a hydraulic network from the design. It should be noted that the number of cycles inherent in pressure ripple is much higher than the number of cycles considered in the validation test and therefore the allowable stress for the materials is reduced.

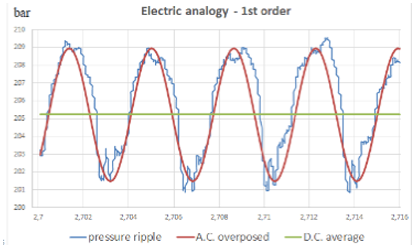

ELECTRIC ANALOGY

The oil flow can be seen as a constant mean value (direct current in the electrical analogy), with a superimposed ripple (alternate current). The hydraulic network responds to the flow ripple with a pressure ripple. In the electrical analogy, the oil flow is the current while the pressure is the voltage.

APPLICATION FIELDS

V-BOX® can be applied to ALL hydraulic circuits with direct benefits on the reliability of the components connected to it, furthermore the simultaneous action of reducing the vibrations of the structures and the noise emissions makes it a fundamental accessory for applications where every day need a reduction of noise and vibrations, such as pleasure craft field, yachts, defense field, industrial plants with nearby operators, earthmoving machinery / tractors, self-propelled vehicles for street cleaning, and so on.

IT CAN BE INSTALLED ON ANY EXISTING SYSTEM!

The worldwide road to electrification aims to eliminate endothermic engines, which with their noise largely cover their drived hydraulic systems noise.

In addition to increasing the reliability of the system, it reduces noise and vibrations without altering the structure of the system, being able to be inserted both in line and in derivation.